From the very beginnings of the game of bowls, most clubs bowled on a green constructed largely of local top soil, built, prepared and seeded by the club members, perhaps with the help of a local gardener or farmer. Maintenance was largely mowing, turning the rinks on flat greens, keeping the surface clear of debris and worm casts and an occasional roll before a big match. In the autumn, a squad of members would descend on the green with forks to aerate or spike the green, before putting it to bed for the winter with a final cut and perhaps a bag of fertiliser.

After the War, as people gradually found time to play and practice their game a little more, and in a similar way to many other sports, there was a desire for continuous improvement of the green surface to make it faster, smoother and more consistent and more predictable to play well on.

From around 1960 golf greenkeepers had started taking note of a new development from America, namely the USGA Specification for Putting Green Construction or the USGA Spec as it is known in greenkeeping circles. Very briefly, the USGA Spec aims to faithfully recreate the putting conditions found on the traditional links golf courses on the east coast of Scotland, consistently and economically on new golf course construction developments.

The USGA Spec is consistently improved upon and is a very big deal among golf greenkeepers, designers and constructors and quite righty so. Although it is continually mis-represented as unsuitable for the UK and Europe, this is nonsense and the specification when understood fully and followed correctly is a very reliable, if expensive way to create consistently high performing golf greens.

The critical part of the previous paragraph is the part that says:

“understood fully and followed correctly”

It takes a good bit of reading and absorbing the USGA Spec to understand it to a competent level, but even then there is no substitute for direct, hands on experience of working with it and implementing it on several projects. Only then, will a greenkeeper get to grips with it and fully understand what the Spec is designed to deliver.

From the admittedly very privileged viewpoint of 50 years later, hindsight is 20/20 after-all, it is now clear that a great many UK greenkeepers understood just a little bit of the Spec. That little bit, unfortunately was that the rootzone material used to grow the grass on in the USGA Spec is “Very Sandy”. Well of course it is, it aims to copy the seaside links!

This was all that was needed for the industry to kick into full sand selling mode and frequent and routine top-dressing of inland golf greens became the norm. Many bowling greens followed suit, either advised by a local golf greenkeeper or by sand salesmen.

And, funnily enough, this was not a bad idea and greens improved dramatically. By hollow tining to remove some of the heavy local soil and replacing it with a 3 tonne dressing of a sandy loam top-dressing, the rootzone of many bowling greens was improved beyond recognition through the 1960’s and 70’s. They drained better, they played better, were smoother, faster and more consistent. They sustained the fine grasses and were relatively easy to maintain.

Meantime, any thought of continuing to learn about the intricacies of the Spec were forgotten about and one key aspect was overlooked. The USGA Spec gives guidance specifically on a method for building greens, a relatively finite set of guidelines when compared to maintaining greens. The Spec outlines how the green should end up at the end of construction and the idea is that it is maintained in that state forever. If you see greenkeepers top-dressing their very expensive USGA Spec constructed greens, they are not adding more sand, because they are under strict instructions to only apply material that matches the original rootzone exactly in terms of mineral content, particle size distribution, organic matter and even particle hardness and shape. If they use anything else, then they are undermining and unravelling a very expensive investment. Of course this has happened many times and the initial investment has been a waste of money, time and effort.

Meantime, the greenkeepers looking after UK golf and bowling greens where continuing to apply the magic dust every year that seemed to be making their greens better and better each year, but this was a ticking time-bomb just waiting for a very critical tipping point to be reached. That tipping point is what I’ve termed Peak Sand. Through the 1960’s and 1970’s, the addition of sandy loam top-dressings had progressed to simply applying the much cheaper straight sand, sometimes directly onto the surface where it formed layers and buried thatch, and sometimes after hollow tining where at least it had a chance of being incorporated into the soil profile and mixed over time into a homogenous sand/soil mix by the activities of the earthworms.

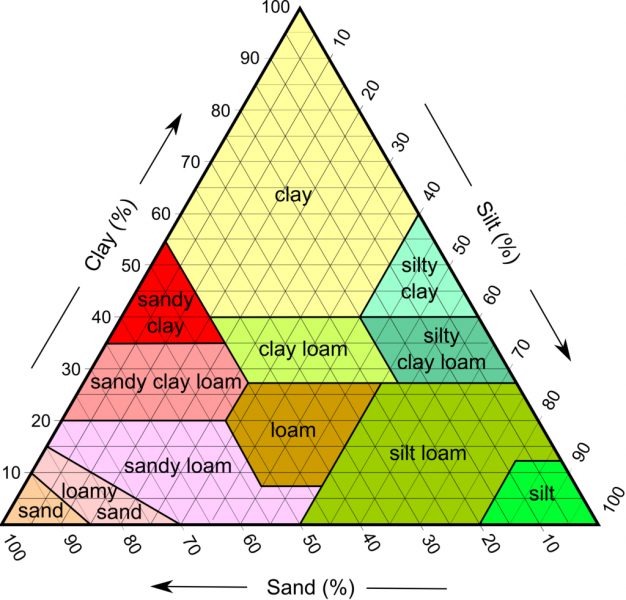

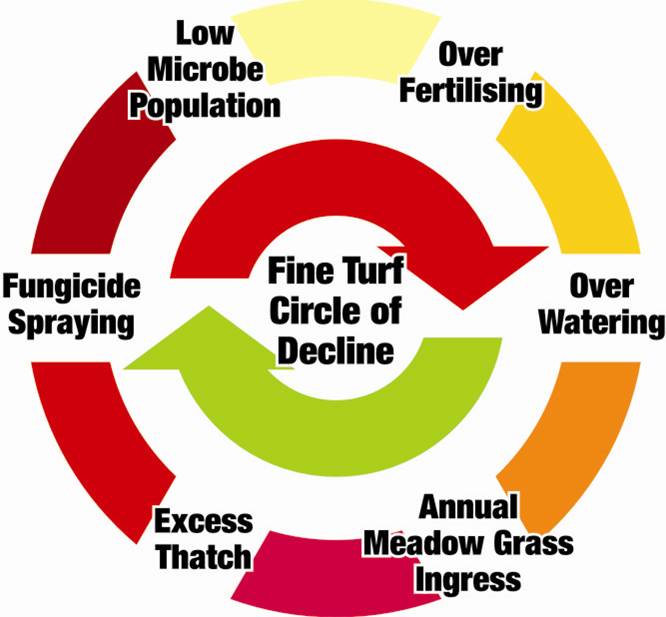

Then the Peak Sand tipping point was reached for many bowling greens in the early 1980’s, but by now the sand top-dressing ritual was so well established that almost nobody questioned it, or even suspected its involvement in a whole series of problems I’ve termed the Circle of Decline. A very high proportion of the greens I do Soil Reports for now register as Sand on the Soil Texture Triangle:

One of the early and now very persistent signs that Peak Sand had been reached was Localised Dry Patch (LDP), which causes the soil on large areas and even whole greens to resist moisture. The soil has become Hydrophobic. Water will lie on the green surface for a long time and the soil underneath will remain powder dry and unable to support plant life. The result is large brown patches on the surface where the thatch eventually dries out so much that it becomes hard and brittle. At this point it will shrink to below surface level, causing large pans of low lying turf which of course affect the performance of the green to a level that is unacceptable.

Soils are made up of Minerals, Organic Material and Space. The mineral component consists of Sand, Silt and Clay. The finer Clay particles, along with Organic Matter (humus) are responsible for nutrient and moisture retention. However, when the Sand component percentage is in the 90’s, there is little scope left for moisture and nutrient retention. In addition to this Sand is inert and doesn’t support a healthy soil microbe population.

Typically, these same greens will have big expanses of moss in winter, very low nutrient retention as explained and great difficulties with surface consistency due to thatch production. Organic matter and microbes are essential for the continued natural re-cycling of dead plant material which is destined to become thatch in their absence.

Action Plan

So, those are the problems facing a great many bowling greens in the UK and their background in the greenkeeping practices that in many cases still persist to this day. BUT, what can be done? Here is my Action plan for you if you have these problems:

- Stop Top-Dressing and cancel your sand order today, before another 3 tonnes is applied to add insult to injury

- Stop obsessing over Symptoms like moss, weeds and an unpredictable playing surface…go straight to the root causes of these problems and deal with Soil Health First.

- Have a Soil Analysis carried out so that you can obtain a report and plan based specifically on your green’s conditions

- Start taking remedial action to counteract the problems of Nutrient, Moisture and Microbial Deficiencies.

- Start to apply a consistent Baseline Greenkeeping Programme that aims to build a healthy percentage of Organic Matter, a healthy Microbe Population and which encourages the fine perennial grasses.

- Undertake consistent remedial action on Hydrophobic Soil

I consider myself relatively lucky to have some soil Science background from my days in agric college and follow a lot of your science on Green’s makeup. I agree that sustaining life in a totally inert medium is more complicated than sewing seed! What I have believed in though is that adding sand prevents the inorganic decay of thatchand creation of Black Layer and preventing oxygen moving down through the profile and with that in mind I am quietly increasing the quantity of sand we are applying. From 50 ton per hectare of green heading towards 100 t. How do We Overcome that problem with less sand?