Winter has a tendency to disappear before we have had a chance to organise all of the winter work properly. In particular, I find that mower maintenance is often left to the last minute and not enough regular maintenance is carried out to the blade and cylinder.

Last time, we used all of our senses (nearly) to evaluate the current condition of the green in order to formulate a plan for getting the green ready for opening day. I hope you’ve had time to get a list together, because I want to focus on dealing with the issues you’ve found in the next article in this series. Today though, it’s a timely reminder that we’re still in winter mode and also that we need to think about getting the mower ready.

Two important points:

- We are still in Winter Maintenance mode despite Opening Day looming on the horizon.

- It’s easy to undo a lot of good work with an ill prepared mower.

De-compacting with the Slit Tiner

This means that the vital winter maintenance detailed in the Performance Greens Programme must go on and one of the most important of these operations is deep slit tining.

Regular deep slit tining to 150mm from October to March is still the most effective method of de-compacting greens and of maintaining them at a manageable level of compaction, without causing damage below the rootzone layer. The trick with this method is that it has a cumulative effect and it is the regular repetition of the operation that gives the desired results. When weather conditions allow, this can be done as often as weekly throughout the winter months.

Mower Preparation: Sharp Cylinders and Blades

The cylinder mower we use for green mowing was developed from an old machine first used in the Victorian carpet and textile industries and although the basic principle of the operation of the machine has remained largely unchanged, today’s bowling green mowers are of course very sophisticated developments on the original idea.

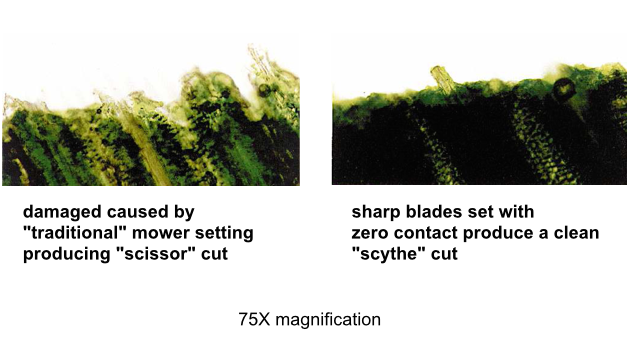

One of the least understood aspects of the cylinder mower is the actual cutting action. It is often assumed that the cylinder acts against the bottom blade, much as a pair of scissors would. In fact the machine is designed to cut more like a scythe; albeit a very sharp scythe.

Back lapping with carborundum paste has unfortunately become a very common practice in greenkeeping for keeping cylinders sharp, but the grass blade finish that results from mowing with a lapped blade producing a scissor fall short of what is required.

It is preferable to have mower cylinders and bottom blades properly ground so that a zero contact setting can be maintained throughout the season.

Lapped mowers invariably have to be set down tighter than desired to achieve a satisfactory cut.

Have a look at the photos below:

By achieving the surgical precision cut promoted by properly ground and set up blades, major agronomic benefits will result which you’ll will notice:

- Sharper cylinders produce healthier, stronger, more uniform turf!

- Fertiliser demands are shown to drop, often by considerable amounts.

- Fungal disease occurrence is reduced dramatically.

- Grass is less stressed and takes less time to recover after mowing

- Grass winters better, forming better root growth. This promotes improved drought and heat tolerance, which can result in less reliance upon irrigation in dry periods (less leakage of fluid from ragged leaf ends)

- Newly seeded grass establishes quicker as root growth improves while top growth is less damaged using sharp mowers.

- Green surface consistency, smoothness and speed are more readily achieved and maintained with clean cutting.

Keeping the edge

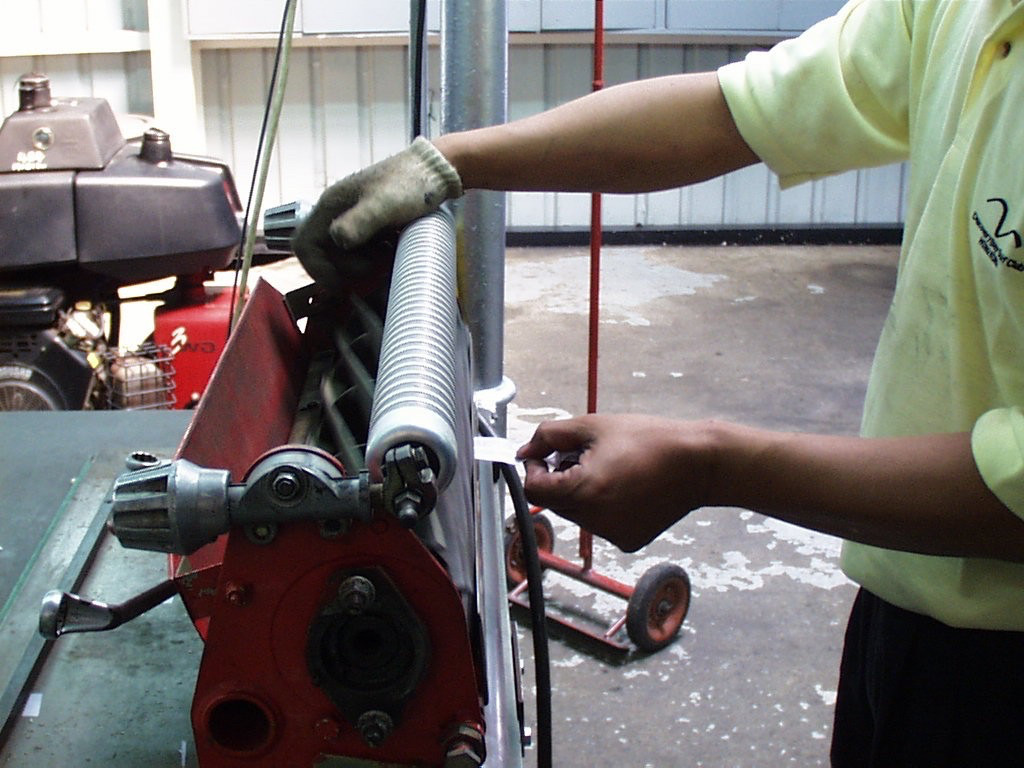

After an annual spin grind and set up of the cylinder and bottom blade, the mower can be kept sharp and set with zero contact between bottom blade and cylinder throughout the season with the minimum of further input.

Bottom blades are ground to specific angles on the top and front edges, according to manufacturers recommendations and if these angles are maintained the need for tightening down of blades to achieve a clean cut is reduced.

One way of doing this is to have your greens contractor use a machine like the Bernhard Rapid Facer to sharpen up the angle on the bottom blade on a monthly basis during the season.

Mowers Last Longer

Of course all of this effort is good for the green, but there is a significant side benefit to be gained by taking this approach to mower set up and maintenance; the mower lasts longer and needs fewer repairs over its life:

- zero contact between blades reduces friction and therefore blades last longer.

- friction causes strain to engines, clutches and bearings so zero contact settings reduce all of this wear, ensuring fewer repairs and less servicing.

Hi John

In the past few years I have waited to mid April until I had my mower serviced and sharpened after it had completed 2 or 3 cuts after the opening of the season.

Although this year due to a mild winter I have cut 4 times at 8mm, I am still wary of damage when I drop to 5.5 mm for the start of the season.

This has proved to be a good move as damage can be done as I’m still topdressing in the autumn.

Re Willie

Downloaded your book on Autumn and Winter Maintenance 2 weeks ago found it so interesting, thanks.

Where do I find the ebook mentioned in the comment?

https://bowls-central.co.uk/product/autumn-and-winter-bowling-green-maintenance-guide/

Hi John.

I understand what you say about back lapping and agree that it is preferable to get the cylinder and bottom blade properly ground.

We have a Dennis FT 610 (24″) and I have just received a quote for the cassette to be sharpened at the nearest Dennis dealership. The quote came to £401.98. That includes a replacement bottom blade, which they always seem to prefer. That is quite simply not affordable on an annual basis for a small private bowling club. That amount is about 25% of the price of a new cassette.

Mike Nencini

Hi Mike

You should be paying around £100ish for a regrind plus an extra £80ish if it needs a new bottom plate. I would say no more than £200. Sometimes you are charged per inch for sharpening and as yours is a 24inch mower may cost the top end of my estimate. You find dealers like sisis and dennis charge top whack like taking your car to its dealership instead of the local garage for half the money. Obviously ask the correct questions and ensure there will be no contact between the cylinder and the plate. I’ll be honest it’s difficult to find somewhere that sharpens mowers correctly so you will need to have a good look around. Seeking advice off other clubs or greenkeepers is worth the trouble. I see you’re near Warrington. I take mine to Cheshire turf machinery in Stockport for the 1st time a couple of weeks ago I’ll let you know how it goes. You can also get mobile sharpeners but they want £150 per mower just for a regrind with a minimum amount of 6 mowers required. I spoke to them and he did offer to squeeze me in if they were in the area but I decided to try C.T.M. first.

It’s possible if you arrange 4 or 5 mowers to be taken to the same club that the mobile sharpeners may be able to help you. It’s testing times for Bowls clubs and if you can help each other out it’s alot easier.

The mobile sharpeners are called Reelsharp!

Might be worth a phone call.

Good luck! 🍀

Regards Ian

Try a golf club for a service. I use our local club a full service, regrind and a bottom blade was under £200. Best place for a bottom blade is Garfitts in Sheffield.

Hi Ian

Thanks for the helpful information and the contacts for sharpening. I’d be interested to know how you got on with Cheshire Turf Machinery.

I’ll do some more checking around with other clubs in our league to see what they do.

Regards

Mike

Hi Mike

Just got our mower back but I haven’t tried it yet. It looks good but we had to have a new cylinder fitted as the last one was couldn’t be sharpened anymore. As you can imagine it had a price.

I asked about sharpening. The cost is £120 and £80 if you need a new bottom blade excluding VAT.

I forgot to ask about the cost of a service unfortunately. Maybe give them a call for a quote.

Personally I get the blades sharpened every year but only have the mower serviced every 2 years and as long as you keep the blades set correctly this will keep the strain off the mower. Just what I do and I find it works well.

Here’s a link on how to put a mower on cut. It’s the best video of this you will find.

https://youtu.be/vabgl7h2p0k?si=-Z3btuqs1rbAVX0O

I’ll let you know how my mower is when I use it again.

Kind Regards

Ian

Here’s one on setting the mower height albeit on a slightly older mower….you know where you actually have to use a spanner and not the fancy pants click adjusters.😀

https://youtu.be/YJu5IDOiq9M?si=P1yrXobcxr4fm8AN

Hi John,

Thanks for the article. You recommend zero contact between the cylinder and bottom plate – what sort of gap would you advise. We have set the clearance to be the smallest size on our feeler gauge which gives a consistent clearance for all the blades along the full width of the cylinder. Is this OK or would you increase it slightly?

Many thanks

John

Hi John

As loose as you can set it while still cutting a thin piece of paper cleanly along the length of the blade.

Regards

John